CALABASAS, CA. (THECOUNT) — Magnesium Alloy burning on a Calabasas hillside dramatically complicated search and rescue efforts following the helicopter crash that killed Kobe Bryant, his young daughter and 7 others on Sunday, according to officials.

What is Magnesium Alloy? And why was it aboard the doomed aircraft in the first place? We did some digging and this is what we found.

|

Advertisement |

Magnesium is a potent solid-solution strengthener when added to aluminum–lithium alloys and also decreases the solubility of lithium in the aluminum matrix and thus enhances the age-hardening response and although the use of magnesium in aerospace structures is now extremely limited, for many years it was used extensively in structural components in aircraft, helicopters and spacecraft because of its light weight. Kobe’s helicopter was equipped with the dangerous material.

There is a widespread belief that a serious safety concern exists with the use of magnesium over its extreme flammability.

Magnesium burns when exposed to high temperature, and therefore poses a major fire risk. However, there have been no cases of aircraft accidents caused by the “ignition of magnesium,” however, once ignited by an external source, dramatically complicated search and rescue efforts by first responder responding to the crash.

The main reason why magnesium is used “sparingly” in modern aircraft, typically less than 1% of the structural mass of large passenger aircraft, is poor corrosion resistance.

Magnesium was originally used in aircraft during the 1940s and for the next thirty years was a common structural material. Magnesium passed through a boom period between the 1950s and early 1970s when military and civilian aircraft were built using hundreds of kilograms of the material. Magnesium was used extensively in airframes, aviation instruments and low-temperature engine components for aircraft, especially fighters and military helicopters, and semi-structural parts for spacecraft and missiles. Since the 1970s, however, the use of magnesium has declined owing to high cost, poor corrosion resistance and other factors, and it is now rarely used in aircraft, spacecraft and missiles, reports ScienceDirect.

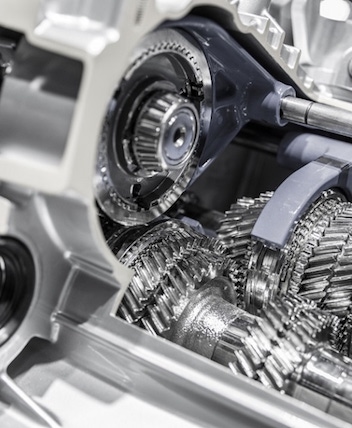

The use of magnesium alloys is now largely confined to engine parts, and common applications are gearboxes and gearbox housings for aircraft and the main transmission housing for helicopters (Fig. 10.1). Magnesium has good damping capacity and therefore is often the material of choice in harsh vibration environments, such as helicopter gearboxes.

DEVELOPING::